UV Rotary Printer: Speed and Quality in One Package

- By:uv digital printing

- 2023-12-11

- 1,297

UV rotary printers have become a go-to choice for high-volume printing needs that require both speed and quality. In this comprehensive guide, we will explore the different types of UV rotary printers, their features, advantages, disadvantages, and how to use them properly.

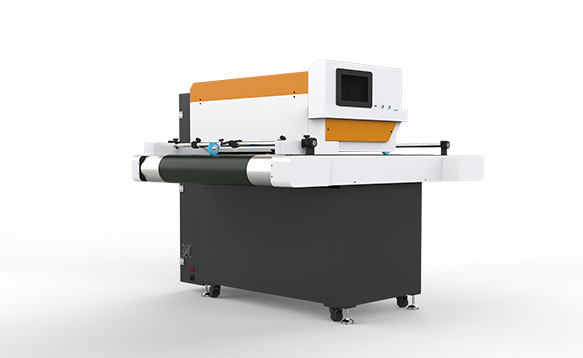

An Introduction to UV Rotary Printers

UV rotary printers are a type of printing equipment that uses UV (ultraviolet) light to cure the ink applied to a substrate as the printer rotates. These printers are typically used for high-volume printing applications that require quick turnaround times and high-quality prints.

Benefits of UV Rotary Printers

UV rotary printers offer several benefits over traditional printing methods:

High-Quality Printing: UV rotary printers use UV ink to achieve a higher level of detail and color depth than many other printing methods, resulting in crisp and clear prints.

Fast Printing: UV rotary printers can print multiple substrates in a short period of time due to their continuous printing process. This greatly increases productivity and allows for faster turnaround times.

Flexibility: UV rotary printers can print on a variety of materials, including paper, cardboard, plastic, and other substances. This provides flexibility in terms of print substrates and applications.

Drawbacks of UV Rotary Printers

Despite its benefits, there are also some disadvantages to using UV rotary printers:

Initial Cost: UV rotary printers are generally more expensive than traditional printers due to their advanced technology and high-quality components.

Ink Cost: UV ink is generally more expensive than standard ink, resulting in higher overall printing costs.

Printer Maintenance: UV rotary printers require regular maintenance to ensure they are in good working condition, including cleaning the printhead and replacing worn parts.

How to Use a UV Rotary Printer

Using a UV rotary printer requires some knowledge and skills. Here are some tips:

Clean the Printing Area: Ensure the area where the printer is placed is clean and dry to avoid any printing issues. Remove any debris or lint from the printing area to ensure smooth operation of the printer.

Load the Substrate: Carefully load the substrate onto the printing cylinder, ensuring it is smooth and free of any creases or tears. Some UV rotary printers have automatic loading systems that make this process easier.

Operate the Printer: Follow the manufacturer’s instructions to operate the printer and select the correct settings for your print job. UV rotary printers typically have user-friendly interfaces that allow you to adjust printing parameters such as print speed, ink density, and substrate temperature.

Unload the Print: Carefully unload the printed substrate once the printing process is complete. Handle with care to avoid damage to the printed image.

Maintaining Your UV Rotary Printer

Regular maintenance is essential to keep your printer in good working condition. Here are some tips:

Clean the Printhead: Clean the printhead regularly to remove any dried ink or debris using the manufacturer’s recommended cleaning solution.

-

Successfully Concluded! Nocai Shenzhen Expo Achieves a Double Harvest of Popularity and Results—We Sincerely Invite You to Visit and Inspect!

2025-10-23 -

Nocai Shenzhen Expo Day 3 is a hit! Tomorrow is the last day—Hall 13, Booth J37-40 is waiting for you!

2025-10-22 -

Shenzhen Gift Expo Day2 Focus: Nocai Bestsellers Set the Venue on Fire, Hidden Exhibition Area Exclusively Open

2025-10-21 -

Grand Opening! Live Coverage of the 33rd Shenzhen Gift Expo – Nocai Presents 5 Core Printing Devices at Booth 13J37-40

2025-10-20 -

27th Cross-Strait Longgang Print & Culture Expo Wraps Up! NOCAI Booth A-G7-2: 4 Core Devices + Pro Services Unlock New Industry Potential

2025-10-20 -

Shenzhen Gifts Fair Concludes Successfully, Nocai Embarks on a New Journey!

2025-08-15 -

Planting for the future- 3.12 Arbor Day, Voluntary action building a green home together!

2025-08-15 -

Women’s Day | “Saluting Your Brilliance, Honoring Trailblazing Women — Nocai Celebrates Every Woman with Festive Blessings & Heartwarming Gifts!”

2025-08-15 -

APPPEXPO Concludes Successfully Today! Nocai and Global Partners Co-“Print” Brilliance, Next Stop Will Be Even More Exciting!

2025-08-15 -

“Charting the Course in the Bay Area • Building Dreams in Dagang” — Guangzhou Nocai Invited to High-Quality Growth Forum in Dagang Town

2025-08-15

-

Stop Stockpiling! UV On-Demand Printing: The Optimal Solution to Inventory & Waste

2026-02-07 -

Breaking Flat Limitations: UV Printing’s Embossed White Ink, Adding Tactile Delights to Designs

2026-02-07 -

How Can a UV Flatbed Printer Transform Your Home Renovation?

2026-01-30 -

6090 UV Printer: The Core Driver Opening a New Era of Short-Run Printing

2026-01-30 -

Digital Tech Revolution: Large-Format Printers Blending Advertising & Art

2026-01-28 -

The Art of UV Printing Color Calibration: Where Technology Interprets the Elegance of Traditional Printing

2026-01-28 -

UV Flatbed Printing Technology Innovation: Diverse Applications in Advertising, Home Furnishings and Crafts

2026-01-16 -

Beyond Material Limits: Exploring the Versatile Applications of the 6090 UV Printer

2026-01-16 -

UV Flatbed Printers: Industrial Potential & Innovative Applications

2025-12-26 -

6090 UV Flatbed Printer: Media Compatibility Study & Detailed Compatible Materials List

2025-12-26

CONTACT US

Guangzhou Nuocai Digital Products Co., Ltd.

If you would like to keep touch with us directly, please go to contact us