Print on Wood Machine: Revolutionizing Woodworking and Design

- By:uv digital printing

- 2023-11-04

- 1,537

In today’s fast-paced and technology-driven world, woodworking is undergoing a transformation. Print on wood machines are revolutionizing the industry by enabling woodworkers to create intricate and beautiful designs with speed and precision. In this article, we will explore the concept of print on wood machines and how they are revolutionizing woodworking and design.

What is a Print on Wood Machine?

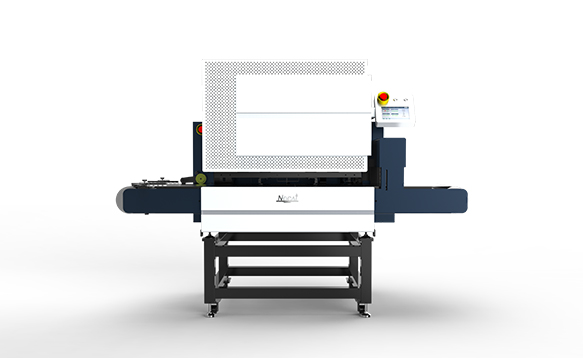

A print on wood machine, also known as a wood printer, is a computer-controlled machine that uses a printing process to transfer an image or design onto a wooden surface. These machines are typically used for printing on small and large wooden items, including furniture, flooring, and décor items.

Benefits of Print on Wood Machines

Print on wood machines offer several benefits to woodworkers and designers, including:

1. High-Quality Printing – Wood printers provide high-resolution printing, resulting in intricate and detailed designs that are difficult to achieve using traditional woodworking methods.

2. Speed and Efficiency – Printing on wood using a machine can significantly reduce production time and increase efficiency, allowing for faster turnaround times and increased productivity.

3. Customization – Wood printers allow for printing on a wide range of wooden items, enabling designers to create unique and personalized designs for their clients.

4. Reduced Material waste -Compared to traditional wood cutting and carving methods, wood printers can accurately print designs, thereby reducing material waste.

5. Sustainability – Printing on wood using machines reduces the need for manual labor, allowing for a more sustainable production process.

Limitations of Print on Wood Machines

Although print on wood machines offer many benefits, they do have some limitations compared to traditional woodworking methods:

1. Initial Investment – Print on wood machines are typically more expensive than traditional woodworking tools, requiring a higher initial investment.

2. Operating Costs – Wood printers require maintenance and specific supplies, such as ink and cleaning products, resulting in higher operating costs.

3. Skill Requirements – Operating a wood printer requires a certain level of technical knowledge and skill, as well as an understanding of design software.

In conclusion, print on wood machines are revolutionizing woodworking and design by enabling woodworkers to create intricate and beautiful designs with speed and efficiency. These machines offer high-quality prints, speed and efficiency, customization, and reduced material waste, making them a popular choice for woodworkers and designers. However, it is important to carefully consider the initial investment, operating costs, and skill requirements before investing in a print on wood machine to ensure it meets your specific needs and goals.

-

Successfully Concluded! Nocai Shenzhen Expo Achieves a Double Harvest of Popularity and Results—We Sincerely Invite You to Visit and Inspect!

2025-10-23 -

Nocai Shenzhen Expo Day 3 is a hit! Tomorrow is the last day—Hall 13, Booth J37-40 is waiting for you!

2025-10-22 -

Shenzhen Gift Expo Day2 Focus: Nocai Bestsellers Set the Venue on Fire, Hidden Exhibition Area Exclusively Open

2025-10-21 -

Grand Opening! Live Coverage of the 33rd Shenzhen Gift Expo – Nocai Presents 5 Core Printing Devices at Booth 13J37-40

2025-10-20 -

27th Cross-Strait Longgang Print & Culture Expo Wraps Up! NOCAI Booth A-G7-2: 4 Core Devices + Pro Services Unlock New Industry Potential

2025-10-20 -

Shenzhen Gifts Fair Concludes Successfully, Nocai Embarks on a New Journey!

2025-08-15 -

Planting for the future- 3.12 Arbor Day, Voluntary action building a green home together!

2025-08-15 -

Women’s Day | “Saluting Your Brilliance, Honoring Trailblazing Women — Nocai Celebrates Every Woman with Festive Blessings & Heartwarming Gifts!”

2025-08-15 -

APPPEXPO Concludes Successfully Today! Nocai and Global Partners Co-“Print” Brilliance, Next Stop Will Be Even More Exciting!

2025-08-15 -

“Charting the Course in the Bay Area • Building Dreams in Dagang” — Guangzhou Nocai Invited to High-Quality Growth Forum in Dagang Town

2025-08-15

-

Digital Tech Revolution: Large-Format Printers Blending Advertising & Art

2026-01-28 -

The Art of UV Printing Color Calibration: Where Technology Interprets the Elegance of Traditional Printing

2026-01-28 -

UV Flatbed Printing Technology Innovation: Diverse Applications in Advertising, Home Furnishings and Crafts

2026-01-16 -

Beyond Material Limits: Exploring the Versatile Applications of the 6090 UV Printer

2026-01-16 -

UV Flatbed Printers: Industrial Potential & Innovative Applications

2025-12-26 -

6090 UV Flatbed Printer: Media Compatibility Study & Detailed Compatible Materials List

2025-12-26 -

“Print first, then form” or “Form first, then print”? — Process choice in collaborative manufacturing

2025-12-18 -

What special effects can cylinder printer achieve? It makes each bottle of wine into a work of art.

2025-12-18 -

Say Goodbye to “Stringing” & “Ink Piling”: Practical Tips for Fine-Tuning UV Printer Nozzle Height

2025-12-11 -

The Business of Custom Phone Cases: How a UV Printer Unlocks Thousands of Creative Ideas

2025-12-11

CONTACT US

Guangzhou Nuocai Digital Products Co., Ltd.

If you would like to keep touch with us directly, please go to contact us